Dispelling the myths

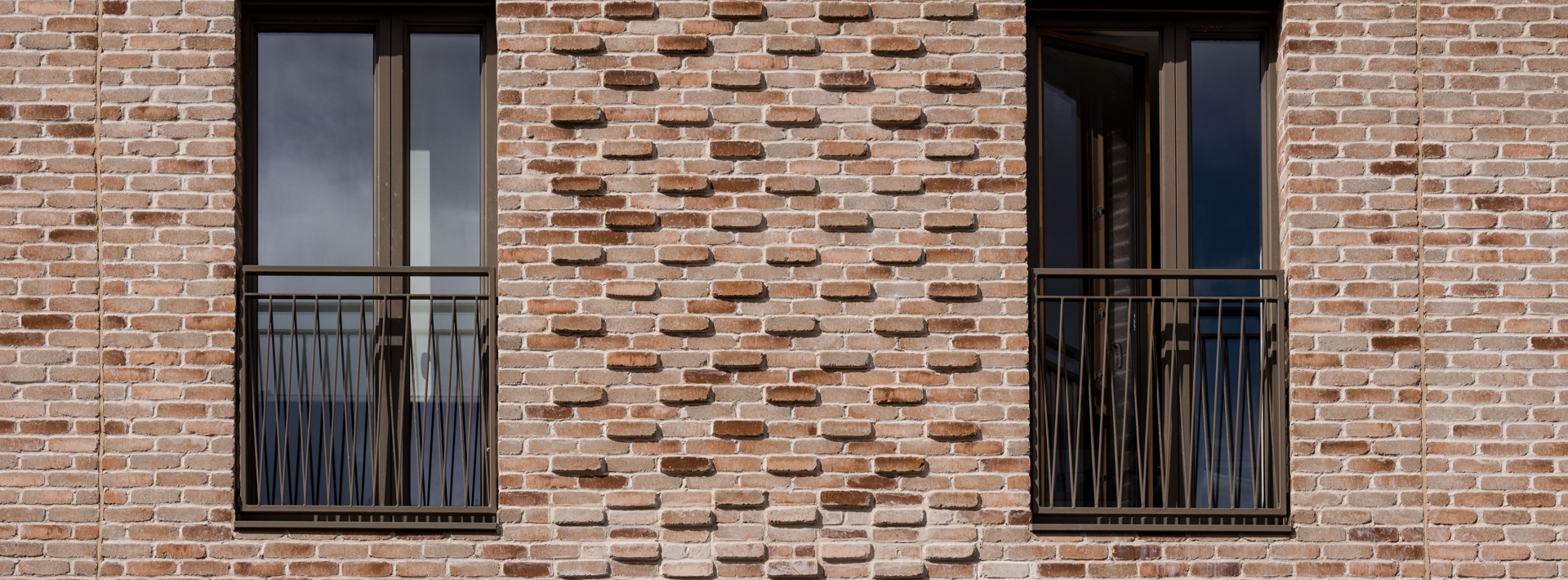

Brick by Brick

Concrete facing brick myths

You'll find a lot of misinformation surrounding the concrete brick in the construction industry, so we're here to break through those myths one brick at a time.

Hear about it from a respected brickwork contractor

Kevin Cafferty, Commericial Director for Marshalls Bricks and Masonry, teamed up with Lesterose Scotland to get their thoughts on concrete bricks - take a look at the video below to see what they had to say.

Say hello to our concrete bricks

Dive into the full range of concrete bricks Marshalls Bricks and Masonry has to offer