Blog

The purely technical

At its most basic, concrete is a simple mix of cement, water and aggregate (sand/stone). When mixed together, the cement and water form a paste that adheres to the surface of every aggregate particle. Through a chemical reaction known as hydration, the cement binder hardens and strengthens to form a network of bonds that bind the aggregates together into a solid mass. It’s this unique process that explains the incredible versatility of concrete – supremely workable when fluid, yet remarkably strong and durable when fully cured.

In order to fully exploit the huge potential of concrete, many specialised mixes exist, involving ever more complex proprietary recipes to satisfy specific technical requirements, properties and aesthetics.

Credit : Portland Cement Association>

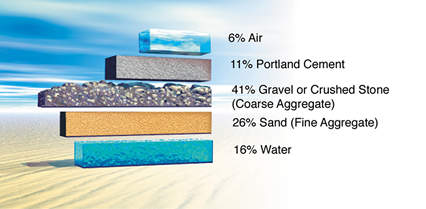

The fundamental characteristics of concrete are determined by both the qualities of the constituent elements and, more specifically, the ratios of each. Careful proportioning and mixing of the ingredients is key to achieving a durable concrete and the balance between water : cement : aggregate is critical. Too much or too little of any element will lead to problems such as difficult pouring, poor finished surfaces, or overly porous concrete that is prone to shrinkage and cracking. A typical concrete mix is 10-15% cement, 60- 75% aggregate, 15-20% water and a proportion of air.

While economics are always an important consideration, the reduction of more costly high quality constituents (eg cement) will inevitably be a false economy, leading to a shorter life in use. Cement is evidently the most important of the elements, but aggregates also need careful selection, according to the thickness and purpose of the finished product: thinner sections requiring smaller, coarse aggregates, where large construction projects, using in-situ poured concrete, might incorporate aggregates up to 150mm in diameter. Clean and graded particle sizes, from sands through to larger elements, are also desirable to ensure an even coating of every particle by the cement paste. Most water is suitable for concrete manufacture, although excessive impurities (such as chlorides or sulphates) can affect setting time and concrete strength, and may also cause efflorescence, staining and corrosion of steel reinforcement. In general, higher quality concretes are produced by lowering the water-cement ratio as far as possible, without sacrificing the workability of the mix.

Forming & Curing

Cement is affected by a chemical reaction that begins with the addition of water so that, soon after the aggregates, water, and the cement are combined, the mixture starts to harden due to a process called hydration. When this happens, nodes form on the surface of each cement particle, growing and expanding until they link up with nodes from other cement particles or adhere to adjacent aggregates. This process results in progressive hardening, and strength development of the concrete.

This can be a relatively rapid process and, once the concrete is thoroughly mixed and fluid, it must be placed in forms before the mixture becomes unworkable. Once poured, the concrete needs to be consolidated in order to compact it into the form and to eliminate pockets of air (after pouring, as much as 20% air may be entrapped, particularly where complex reinforcement has been installed). Consolidation is often carried out by vibrating the concrete, removing voids that would otherwise lead to increased permeability and hence strength reduction.

The rate of curing depends upon the composition of the cement, mix proportions, and prevailing moisture and temperature conditions. The majority of hydration and strength gain take place within the first month, but hydration continues at a slower rate for many years and concrete continues to get stronger as it ages. Today’s modern pre cast concretes often contain additives that speed up the curing process and allow rapid de-moulding of the finished pieces.

Concrete development

Although for many years concrete included no additional strengthening materials, considerably greater strength can be gained through the addition of reinforcement. Since the 19th Century, most commonly mild steel bars or mesh (ie rebar) – whether galvanised or not – are used, although stainless steel reinforcement is often a preferred alternative. More recently, the addition of synthetic structural fibre reinforcement (such as STRUX™) to the concrete mix offers increased resistance to failure from impact or overloading and increases the durability of the cured concrete, maintaining long term integrity and performance.

The demand for more heavily reinforced concrete, and ever more complex formwork, has brought about the development of new technology in areas such as self compacting concrete (SCC). This is a high-performance concrete that flows easily into the tight and constricted spaces of slim or complex moulds, and passes through rebar, without the need for vibration. The key to SCC is the creation of a mixture that is fluid and in order to achieve the required fluidity, which is dependent upon element shape, desired surface finish, and travel distance, the introduction of plasticisers is necessary to reduce the water requirement and slow slump loss. In addition, higher percentages of fine materials (or additional admixtures) are required to produce a stable mixture ie one that does not segregate. These proprietary mix designs require enormous amounts of research and development, and constant verification to confirm that any gains made in terms of pouring and forming do not compromise long term durability.

In recent years, enormous strides have also been made in the development of high and ultra-high performance concrete (HPC and UHPC). The ultimate in terms of contemporary concrete technology, design outcomes can be extraordinary, allowing for innovative forms that seem to defy logic, and are certainly changing our perception of concrete. These highly technical concretes rely on the addition of minimal water to the mix, and several additives (such as fibre reinforcement and plasticisers) are required to prevent cement particles clumping, and the mix being weakened. The manufacturing process requires enormous precision and stringent quality control, but overcoming these constraints is certainly worthwhile, leading to these excellent performance characteristics:

- remarkable compressive tensile and strengths compared to conventional concrete

- highly mouldable, with minimal steel reinforcement that enables extremely slim sections and elegant proportions

- extremely high quality surface finishes

- low porosity and chloride impermeability for excellent corrosion and freeze:thaw resistance and hence minimal maintenance

It doesn’t seem too extreme to suggest that UHPC may well be the most important technological breakthrough in concrete since its invention and it offers the greatest potential to entirely transform both product design and lifetimes.