Blog

The Advantages of Ready Mix Mortar

When it comes to mortar in housebuilding and construction in general, the right mortar mix and readiness on site when needed are essential.

Although the ready mixed mortar (often called factory batched mortar) is increasing in popularity, there is still some confusion around whether it’s a better option than site-mixed mortar and the dry silo option.

Here, we take a look at the benefits of ready-to-use mortar compared to dry silo and site mixed and compare the costs of all the mortar options.

What are the main types of mortar used in the construction industry?

Site-mixed mortar

The most common type of mortar mix is site mixed. Traditionally, it has been seen as the best way to ensure the mortar is ready when needed, which can result in less wastage.

In recent years, there have been concerns about crumbling mortar in house buildings due to poor mortar mix ratios, which reduce strength and durability. There are also health and safety worries relating to cement inhalation and the dangers of skin contact, which ready-mix-mortar avoids.

Dry silo mortar

Once a project is underway, it can be common to have a silo delivered to the site, giving workers a ready supply of mortar that’s mixed to the correct quantities for the job.

This is a more reliable option than site-mixed, where the mortar quality is concerned, but it still relies on accurate water being added. There are also several different costs associated with the silo, such as getting it in place and taking it down, which can also be affected by severe weather and loss of power.

Ready to use mortar

Generally delivered to site with a quick turnaround; factory batched mortar can be used straight away, and the tubs positioned around the site close to where bricklayers are working. This not only increases productivity but also reduces manual handling, mess and dust.

In the case of Mortars & Screeds, there’s a minimum two-day retardation on the product, giving less wastage. However, when it comes to the cost of factory-batched mortar, there is a misconception that it’s the most expensive option, so keep reading below to find out if that’s still the case.

Five advantages of ready-mixed mortar

Compared to dry silo and site-mixed mortars, ready-mix has several key advantages to increase the efficiency, quality and cost-effectiveness of your construction projects.

Here are five reasons why you should use ready-mix mortar in your next construction project.

1. Consistent quality

Ready-to-use mortar is produced in controlled environments with precise measurements. This ensures a uniform and high-quality product in every batch, leading to better consistency and performance, ultimately benefiting the structural integrity of your projects.

2. Saves time and labour

Using ready-mixed mortar eliminates the need for on-site mixing, which reduces construction time and labour costs, meaning your workforce can focus on other tasks and streamline efficiencies.

3. Reduces waste

Ready-mixed mortar is prepared and delivered to exact project specifications, minimising waste, saving money and contributing to your project's environmental goals.

4. Enhanced durability

The mortar is produced using specialist equipment and goes through quality control processes before delivery. This results in a higher-quality, more durable product that could reduce maintenance costs in the long term.

5. Environmental benefits

Ready-mix production processes are designed to produce less dust pollution and incorporate recycled materials without compromising on quality. This reduces the carbon footprint of your project and ensures a cleaner product.

Which type of mortar is most effective for the construction industry?

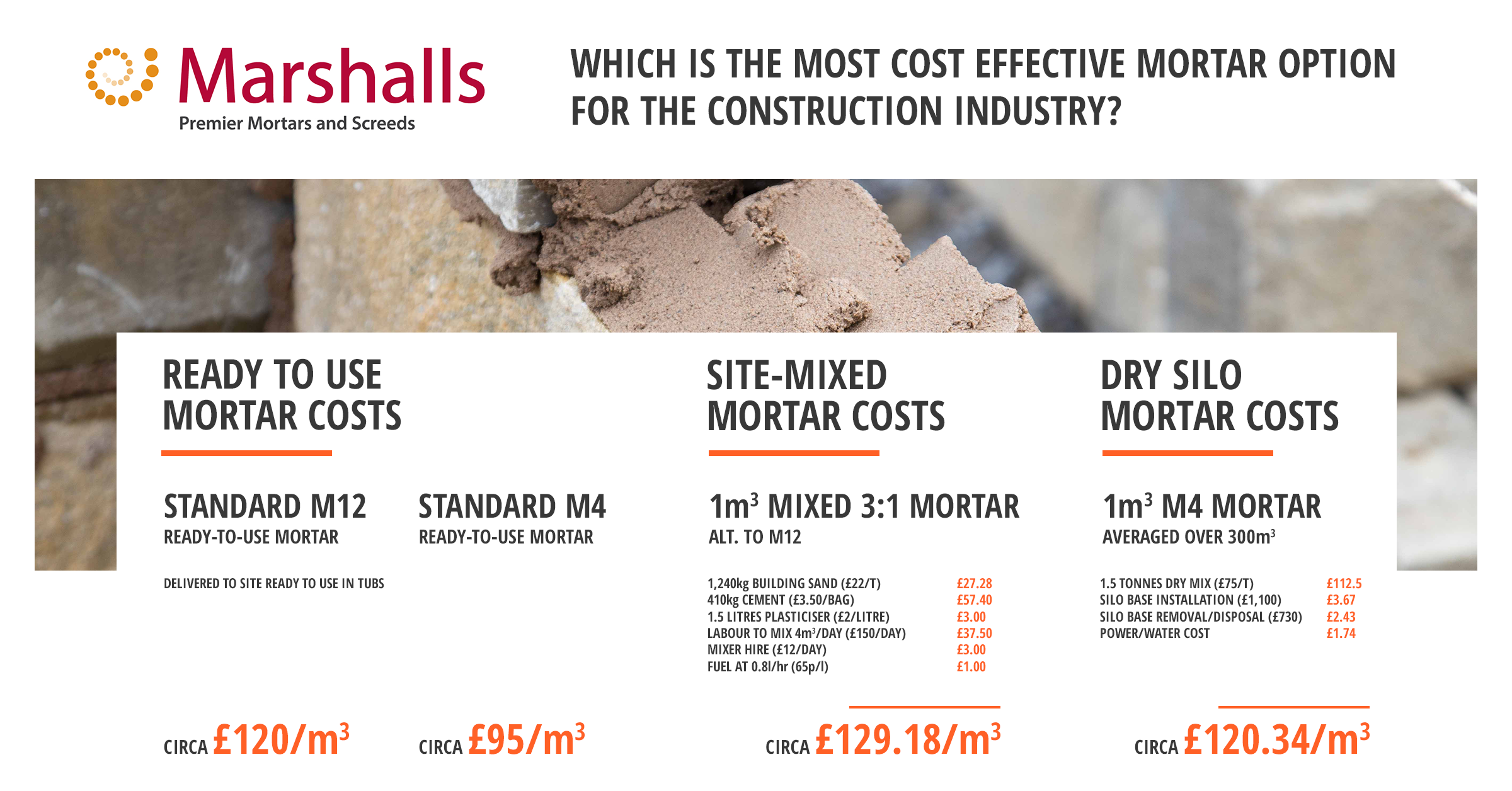

The infographic below shows the rough comparative costs of the three mortar mix options discussed in this article.

Based on pricing by Marshalls Mortars & Screeds (all costs are an approximation based on available data as of August 2019), ready-to-use mortar is shown to be the most cost-effective option.

Unlike site-mixed mortar, there is no cost for additional labour with a delivered product, and you don’t have the installation, removal and power costs of a dry silo.

Not only is ready-to-use Mortar the most cost-effective option out of the three mortar types discussed here, but it is also the only way to ensure that all elements of the mix are accurately recorded.

If you add too much water to a dry silo mix, the mortar won’t dry out fast enough and pointing will be difficult.

With an on-site mix, the wrong quantities of any of the elements will result in crumbling mortar. This means it will be unfit for purpose and could potentially fail.

Buy ready-to-use mortar from Marshalls Mortars & Screeds

With 14 sites across the UK and a 24-hour turnaround time, Marshalls Mortars and Screeds can have superior-quality mortar on site just ahead of when it’s needed.

With a strict quality control process, all of our ready-to-use mortars and screeds are fit for purpose and adhere to the relevant British Standards.

You can even buy ready-to-use mortar in several colours so your commercial building project will look as good as it functions.