Background

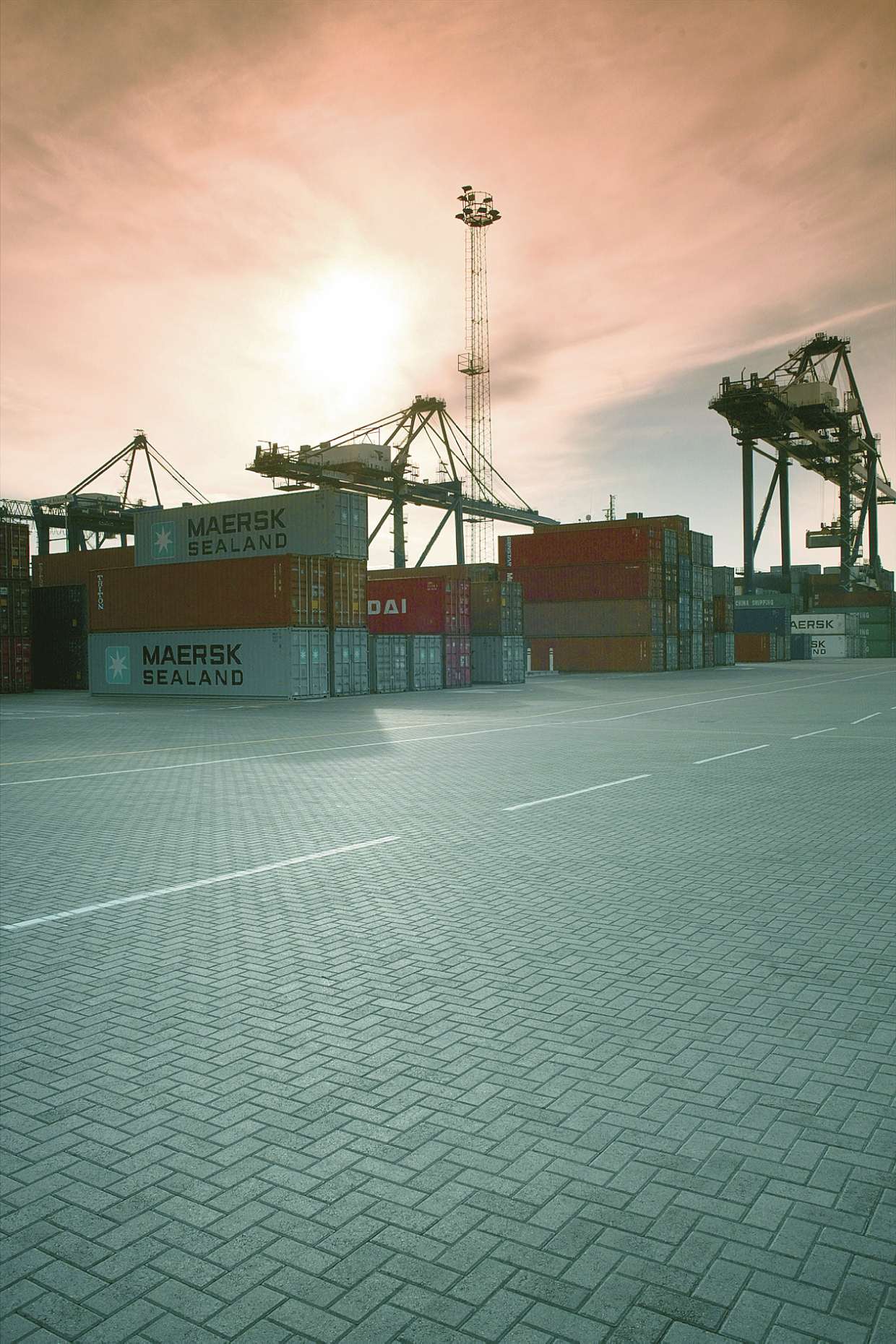

The Port of Felixstowe in Suffolk is Britain’s busiest container port and one of the largest in Europe, handling almost half of Britain’s containerised trade. In 2008 work began on the construction and reconfiguration of Felixstowe South Terminal. The plans for the Deepwater Container Facility were to provide an additional 730 linear metres of quay wall which could accommodate the world’s new ultra-size container vessels.

Challenge

With the new quay housing five cranes weighing 1,800 tonnes each, and up to 270,000m² of container stacking and handling area to be trafficked by gantry cranes and HGVs, a surface solution was needed which could withstand these extreme conditions. The client issued a demanding specification for the manufacture and testing of Concrete Block Paving which exceeded the requirements of the British Standard. This element of the build programme compressed to just one year.

Solution

Marshalls was able to respond rapidly to the specification and programme requirements with their proven Machine Lay (ML) Concrete Block Paving offer. Marshalls Keyblok ML45 is the fastest method for installing large areas of concrete Client: Hutchinson Port Holdings, Port of Felixstowe Contractor: Costain Limited Products Used: Keyblok Machine Lay Block Paving and Titan High Containment Kerb. Prepackaged in their laid formation, packs are delivered to site and layers of 1.28m² (64 blocks) are collected from the pack and installed on the laying course by a powered ride-on machine.

Recognising the advanced specifications, special mix designs and testing models were devised by Marshalls and put into practice for approvals in advance of supply together with a local testing regime to ensure continued compliance. Varying colours were used to distinguish between operational areas across the port pavement. Charcoal was used to differentiate the crane operating area adjacent to the quay wall; Natural was used throughout the container storage area and Red was used to highlight the historical Dock Basin area. In addition, Marshalls also supplied in excess of 400 linear metres of Titan High Containment Kerb for the vehicle operation areas, providing a practical, hydraulically pressed solution with excellent inherent strength.

Benefit

This project provided an outstanding opportunity for Marshalls to demonstrate their combined manufacturing, technical, pre-planning, logistical and projectmanagement expertise to deliver a defect and error free installation over a sustained 12 month period. Marshalls unique manufacturing process ensures that stocks for major installations can be created at speed, held, delivered and installed in sequence, a process that also reduces potential for size and colour variation over large areas.